You are not logged in.

Dear visitor, welcome to WesWorld. If this is your first visit here, please read the Help. It explains in detail how this page works. To use all features of this page, you should consider registering. Please use the registration form, to register here or read more information about the registration process. If you are already registered, please login here.

Quoted

Originally posted by HoOmAn

How were German engines impaired by the lack of specialist metals for exotic alloys?

I heard this played a role in the Jumo 222 desaster?

I heard it had a huge effect on the Germans capailities to use high tempreture resistant alloys which then resulted in less effective engines (power output, fuel consumption etc.)?

How did Germans engines with or without such alloys compare to foreign (especially French, British or American) ones?

If there was such lack and if it had negative effects - what was done to counter that?

Thanks.

This post has been edited 2 times, last edit by "howard" (Sep 1st 2008, 6:00pm)

Quoted

How were German engines impaired by the lack of specialist metals for exotic alloys?

Quoted

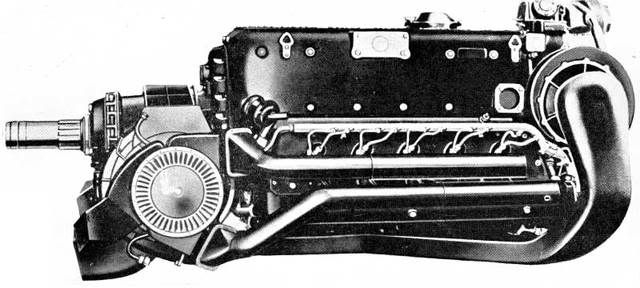

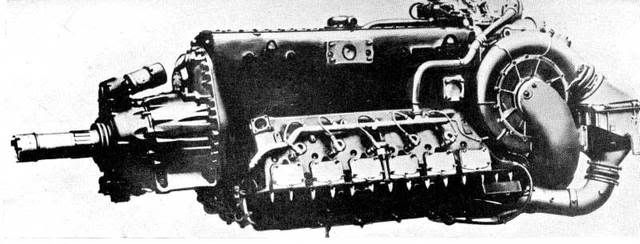

THE BMW 801 RADIAL ENGINE

The BMW 801 twin row radial engine formed the basis of the Focke Wulf fw190 design. This engine has the reputation as being among the better engine designs of WW2 regardless of limitations in German supercharger technology which lead to some failings at high altitude. It also powered many other Luftwaffe aircraft, from the Arado Ar 232A to the Junkers Ju 390.

The Bayerische Motroen Werke (BMW) based in Munich, were manufacturing Pratt and Whitney radials under license in the 1930’s and used this experience to develop its own twin row engine. Despite this, it can be considered an original design incorporating fuel injection and other German features.

A remarkably compact installation, adequate cylinder cooling was obtained using pressure baffling augmented by a magnesium alloy fan geared to turn at 1.72 times engine RPM (3 times propeller speed). An oil tank and cooler are positioned in the nose bowl and are armour plated. The engine mount ring is a sealed unit of square cross-section and also acts as a hydraulic fluid reservoir. Additional streamlining was achieved by the introduction of drag-inducing cowl flaps.

The BMW 801D-2 (fig.6.) was fed by methanol-water injection. Most revolutionary however, was the Kommandogerat. This hydraulicelectric “brain” unit was operated by a single control which was the pilot's throttle lever. It automatically adjusted fuel flow, mixture strength, propeller pitch setting and ignition timing. It also cut in a second stage of the supercharger at the correct altitude. The pilot could, if required, manually set the propeller pitch without altering any of the other settings.

Quoted

Data from Quest for Performance, Jane’s Fighting Aircraft of World War II, and Standard Aircraft Characteristics

General characteristics

* Crew: 1

* Length: 33 ft 7 in (10.24 m)

* Wingspan: 42 ft 10 in (13.06 m)

* Height: 13 ft 1 in (3.99 m)

* Wing area: 334 ft² (31 m²)

* Airfoil: NACA 23015.6 mod root; NACA 23009 tip

* Empty weight: 9,238 lb (4,190 kg)

* Loaded weight: 12,598 lb (5,714 kg)

* Max takeoff weight: 15,415 lb (6,990 kg)

* Powerplant: 1× Pratt & Whitney R-2800-10W "Double Wasp" two-row radial engine with a two-speed two-stage supercharger, 2,000 hp (1,491 kW [29])

* Propellers: 3-blade Hamilton Standard

o Propeller diameter: 13 ft 1 in (4.0 m)

* * Fuel capacity: 250 U.S. gal (946 L) internal; up to 3x 150 U.S. gal (568 L) external drop tanks

* Zero-lift drag coefficient: 0.0211

* Drag area: 7.05 ft² (0.65 m²)

* Aspect ratio: 5.5

Performance

* Maximum speed: 330 knots (380 mph, 610 km/h)

* Stall speed: 73 knots (84 mph, 135 km/h)

* Combat radius: 820 nm (945 mi, 1,520 km)

* Ferry range: 1,330 nm (1,530 mi, 2,460 km)

* Service ceiling 37,300 ft (11,370 m)

* Rate of climb: 3,500 ft/min (17.8 m/s)

* Wing loading: 37.7 lb/ft² (184 kg/m²)

* Power/mass: 0.16 hp/lb (260 W/kg)

* Time-to-altitude: 7.7 min to 20,000 ft (6,100 m)

* Lift-to-drag ratio: 12.2

* Takeoff roll: 799 ft (244 m)

Armament

* Guns:

o either 6× 0.50 in (12.7 mm) M2 Browning machine guns, with 400 rounds/gun, (All F6F-3, and most F6F-5)

o or 2× 20 mm cannon, with 225 rounds/gun

o and 4× 0.50 in (12.7 mm) Browning machine guns with 400 rounds/gun (F6F-5N only)

* Rockets:

o 6 × 5 in (127 mm) HVARs or

o 2 × 11¾ in (298 mm) Tiny Tim unguided rockets

* Bombs: up to 4,000 lb (1,800 kg) full load, including:

o Bombs or TorpedoesFuselage mounted on centreline rack)

+ 1 × 2,000 lb (910 kg) bomb or

+ 1 × Mk.13-3 torpedo;

o Underwing bombs: (F6F-5 had two additional weapons racks either side of fuselage on wing centre-section)

+ 1 × 1,000 lb (450 kg) or

+ 2 × 250 lb (110 kg)

+ 6 × 100 lb (45 kg)

Quoted

Specifications (Fw 190 A-

Data from Fw 190 A8

General characteristics

* Crew: One

* Length: 9.00 m (29 ft 0 in)

* Wingspan: 10.51 m (34 ft 5 in)

* Height: 3.95 m (12 ft 12 in)

* Wing area: 18,30 m² (196.99 ft²)

* Empty weight: 3,200 kg (7,060 lb)

* Loaded weight: 4,417 kg (9,735 lb)

* Max takeoff weight: 4,900 kg (10,800 lb)

* Powerplant: 1× BMW 801 D-2 radial engine, 1,272 kW (1,730 hp); 1,471 kW (2,000 hp) with boost

Performance

* Maximum speed: 656 km/h at 4,800 m, 685 km/h with boost (383 mph at 19,420 ft (5,920 m), 408 mph (657 km/h) with boost)

* Range: 800 km (500 miles)

* Service ceiling 11,410 m (37,430 ft)

* Rate of climb: 13 m/s (2560 feet/min)

* Wing loading: 241 kg/m² (49.4 lb/ft²)

* Power/mass: 0.29 - 0.33 kW/kg (0.18 - 0.21 hp/lb)

Armament

* 2× 13 mm MG 131 machine guns with 475 rounds/gun

* 4× 20 mm MG 151/20 E cannons with 250 rounds/gun in the wing root and 140 rounds/gun outboard.

Specifications (Fw 190 D-9)

General characteristics

* Crew: 1

* Length: 10.20 m (33 ft 5 1/2 in)

* Wingspan: 10.50 m (34 ft 5 in)

* Height: 3.35 m (11 ft 0 in)

* Wing area: 18.30 m² (196.99 ft²)

* Empty weight: 3,490 kg (7,694 lb)

* Loaded weight: 4,350 kg (9,590 lb)

* Max takeoff weight: 4,840 kg (10,670 lb)

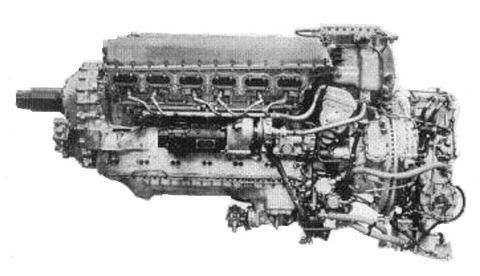

* Powerplant: 1× Junkers Jumo 213 A-1 12-cylinder inverted-Vee piston engine, 1,287 kW, 1,544 kW with boost (1,750 PS / 2,100 PS)

Performance

* Maximum speed: 685 km/h at 6,600 m, 710 km/h at 11,300 m (426 mph at 21,655 ft / 440 mph at 37,000 ft (11,000 m))

* Range: 835 km (519 mi)

* Service ceiling 12,000 m (39,370 ft)

* Rate of climb: 17 m/s (3,300 feet/min)

* Wing loading: 238 kg/m² (48.7 lb/ft²)

* Power/mass: 0.30 - 0.35 kW/kg (0.18 - 0.21 hp/lb)

Armament

* 2× 13 mm MG 131 machine guns

* 2× 20 mm MG 151 cannons

* 1× 500 kg (1,102 lb) SC 500 bomb (optional)

http://www.wwiiaircraftperformance.org/fw190/ptr-1107.pdf

Quoted

I always got the feeling those German engines were 200 to 300 hp behind foreign engines and the Germans somehow had to compensate lost years of technical developments after the Great War. The only exception seems to have been diesel engines - both naval and aviation, right?

This post has been edited 3 times, last edit by "howard" (Sep 2nd 2008, 5:00pm)

Quoted

Originally posted by HoOmAn

So German engine and aircraft engineers worked closely together? Does this happen with other engines too (i.e. DB6xx series)?

Quoted

Having engineers of both the airframe and the engine company work together doesn´t seem to be something special first place. I would have expected it from the British or Americans too for example (RR Griffon into new Spitfire version?). Probably just because it is quite common today....?!

Quoted

Why haven´t others worked on airborne diesels? For example I seem to remember several Martin flying boats exploded in mid-air because of fuel leaks. That couldn´t have happened with diesels - or at least I can´t remember to have ever read about a BV138 exploding because of a fuel leak.

Quoted

I mention flying boats here as this type of aircraft seems best suited for diesels back then - no high speed but range needed, fires less likely and you can share fuel with your navy friends now and then... Well, at least if you´re German. The Allies used patrol for their PT boats after all.

This post has been edited 2 times, last edit by "howard" (Sep 3rd 2008, 7:12pm)

This post has been edited 2 times, last edit by "Red Admiral" (Sep 8th 2008, 7:55pm)

This post has been edited 1 times, last edit by "Red Admiral" (Sep 8th 2008, 8:17pm)

Quoted

Originally posted by Red Admiral

Systems engineering and whole other branches didn't really exist at that point. It was pretty much a case of we've got these engines available and so we'll build an aeroplane around them. It wasn't really until the late 50s until the weapon concept arrived with the interaction between all the pieces being studied to arrive at the best result. This was brought about mainly through the much greater speeds available and the need to intercept nuclear-armed bombers. The complexity of aircraft massively increased as well. Back in the 30s it was possible for a single person to design an entire aircraft, backed up with some people to do detail work. Now you'd have someone working on optimising every single piece.

Engines of the day were fairly complicated with different levels of boost from the supercharger needed depending on throttle, speed and altitude. With the RR engines you had automatic boost control with the option to set manually if needed (to get very economical cruising). You've also got variable area flaps on the radiators depending on the throttle setting. Most were fairly simple two or three position that you opened or closed depending on engine temperature. There were lots of simple little things that could have been automatically to reduce pilot workload considerably.

Quoted

Originally posted by Red Admiral

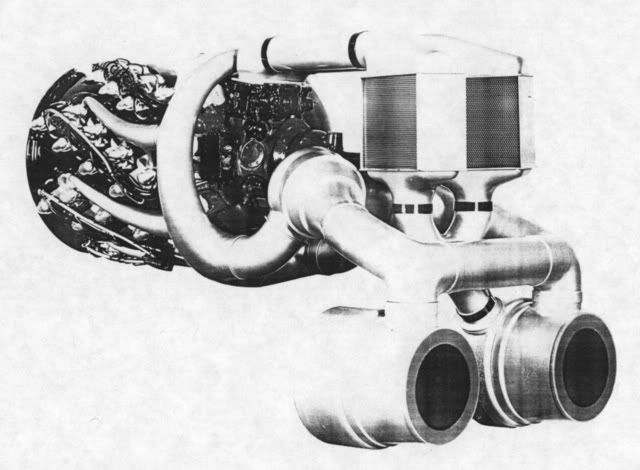

The R-4360 is considerably larger than the others with around 250% the capacity of the Merlin (displacement x rpm). This is for the postwar VDT variant as well, I can't find any pictures showing the earlier turbosupercharged arrangement. But yes, that is a real picture with the correct size turbochargers and aftercoolers.

Forum Software: Burning Board® Lite 2.1.2 pl 1, developed by WoltLab® GmbH